A very popular method to help decrease heat from roofs in Pakistan is Built up Roofing, which is only available for flat or less sloped rooftops. Through coating with bitumen or asphalt, along with application of reasonable minerals as a defensive layer using a bunch of rocks, stones and several other light-colored marbles with better solar reflection.

At rockline enterprises we have all our focus on quality work. We assure you that the roof coating we will provide will be of international standards and economical. You will be amazed on how your expenses will decrease in the summers due to fewer bills.

It’s quite intelligible for people to turn on their air conditioning as the climate gets worse with each passing day with high temperatures flying the mercury level to the roof. But in Pakistan, where no steady electricity is present for households, being entirely dependent on-air conditioning is not wise at all. The weather of Pakistan is extremely hot with unstable rain. In order to decrease the heat from roofs in Pakistan, we have given clear, effective, tried and tested methods that would doubtlessly help you defend your roof from water and heat.

Apply cool roof coatings:

Cool roof coating is the best option for all types of roof in Pakistan, whether it’s plain, or slanting. Through the use of chemically pitch covering over the rooftop upgrade the usage of high solar reflectivity that lessens the entire heat radiation to insert into the texture. The most familiar roof cool coatings present in Pakistan are contentious coating and Elastomeric coating. These chemicals are practiced with spray, roller, brush or sponge over the roof. utterly by covering several layers of these chemicals.

Dominant weather of Pakistan is very hot with unpredictable rains. Unfortunately, most of the residential houses have not been constructed by taking weather into consideration during construction that’s why most of our houses are absorb sun heat too much directly and remain hot and warm making life very tough of their residents. Heat Proofing in Pakistan

Being the country of dominantly poor people, all the people of Pakistan cannot afford air-conditioners or other cooling equipment. To solve these entire problems and to give Pakistan a cool living environment, we have launched special Roof heat proofing services in Pakistan to facilitate the residents living here! Heat Proofing in Pakistan

Heat comes in three forms, ultra-violet (UV), visible light and infrared (IR). Isothane will block all three, especially IR, which is responsible for roughly 57% of heat load on building’s roof. It can be applied on the roof and side of the building such as RCC, metal, felt, asphalt, aluminum, wood, and rubber, it can also be used on the interior surfaces of home or building. Thus it can block heat up to 45%. Heat Proofing in Pakistan

With having high elongation & strong bonding additional properties, it can create excellent waterproof barrier against all type of roofs & exterior walls. Damaged due to hot weather conditions, it also helps to prevent building expansion/contraction & thermal shocks.Rockline Chemical provides extreamly affective solution for roof heat proofing in pakistan, Heat Proofing in Pakistan

Benefits of roof heat proofing coating- Save your electricity bill up to 30%

- AC cooling enhances up to 50%

- Heat proof treatment also support up to 60%

- You can walk bootless on top of the roof in a shiny summer day

- Rockline products have no side effects

- Reduction 8-10 °C degree in temperature

- Rockline heat proofing products have an inherent extinguishing quality and will not support flame

- Extremely Light weight-reduces dead weight.

- Energy efficient-reduces heating/coolling cost.

- Resistant to Ultra violet rays.

- Ease of application.

- Lexible, Anti-Rust and Anti-Fungus.

- Bonds equally well to porous and non-porous surfaces. positive adhesion qualities.

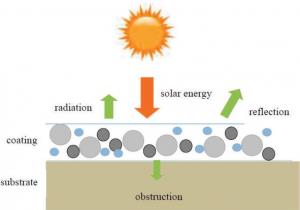

Chemical concept of roof heat insulation & function of coating

The surface temperature of roof rises due to the accumulated heat when it absorbs solar energy, the excessive temperature caused by solar radiation will result in many inconveniences and even troubles in industrial production and daily life; in order to maintain the proper temperature of the roof , a large amount of energy is consumed i.e Air Conditioner system Rockline Chemical provides extreamly affective solution for roof heat proofing in pakistan, Heat Proofing in Pakistan

The development of effective and economic thermal insulation materials is the key to meet the urgent needs for energy saving and emission reduction. In the face of variety of choices of thermal insulation materials, thermal insulation coating become more and more popular due to its good thermal insulation performance, economic, easy to use, and adaptability for a wide range of substrates. With the thermal insulation functional fillers (briefly called fillers in the following text) in coating system, the films can show a certain thermal insulation effect by reflecting, radiating, or isolating heat. As a result, when covered by thermal insulation coatings, the surface temperature of object would be greatly decreased. In this case, a large amount of energy consumed for cooling down the objects exposed to sunlight could be saved, which means the energy consumption can be reduced effectively by just covering with a thermal insulation coating on the surface of object. Heat Proofing in Pakistan

In hot summer, the storage tank for oil, gas, chemical, etc. required to be cooled by water spray regularly. Otherwise, high temperatures can cause excessive volatile organic compounds volatilization and even explosion. But this cooling method not only wastes a lot of water and electricity costs, but also affects the tank equipment maintenance. Heat Proofing in Pakistan

The mechanism of thermal insulation coatings

According to the heat transfer theory, the solar radiation is mainly transmitted to the roof as heat, so when the surface of the object absorbs sunlight, the heat can transfer from the surface to the inside of roof. As a result, the temperature of the roof rises accordingly. But if the roof can be covered with thermal insulation coatings on its surface, most of the extra heat from sunlight can be insulated before it transfers to the surface of the roof. Heat Proofing in Pakistan

The obstructive thermal insulation coating is a kind of passive thermal insulation coating by resisting heat transfer with particular fillers. But as mentioned above, the coatings system always consists of resin, fillers and pigments, additives, and solvents. So, not only the thermal conductivity of fillers but also other materials are crucial to the heat-resist performance of film. In general, pigments, fillers, additives, and film-forming materials with low thermal conductivity are selected to produce an obstructive thermal insulation coating; among them, the fillers with very low thermal conductivity called thermal insulation functional fillers are the key to achieve an excellent thermal insulation performance of the film. Heat Proofing in Pakistan

With these special fillers, the film can stay at a low thermal conductivity and achieve an excellent thermal resistance performance. So, the thermal conductivity (λ) of the functional fillers is generally less than 0.06 W•m−1•K−1 as the λ of air is about 0.0267 W•m−1•K−1, which means quite poor thermal conductivity, so most of the obstructive thermal insulation fillers have a hollow structure. Common thermal insulation functional fillers are materials with a hollow structure, such as, inorganic silicate-based materials, asbestos fibers, expanded perlite, sepiolite, closed-cell perlite, diatomaceous earth, and so on. Closely packed hollow particles in these fillers can form a layer of gas that has a barrier to heat and blocks the “thermal bridge”Rockline Chemical provides extreamly affective solution for roof heat proofing in pakistan, Heat Proofing in Pakistan

Reflective thermal insulation coatings

The film of reflective thermal insulation coatings can reflect solar energy, rather than absorption or resist. Usually, we can use total solar reflectance (TSR) to evaluate the reflectivity of a material. TSR means the ratio of solar energy reflected by a certain surface of material, usually expressed as a percentage. For example, when the TSR value of a particular material is 75%, which means, the material can reflect away 75% of solar energy and only absorb the rest 25% of solar energy. Theoretically, any material can reflect solar energy more or less. As the energy wavelength of solar radiation is mainly concentrated at the range of 200–2500 nm, to specific, about 50% is distributed in the visible spectrum (from 400 to 720 nm) and 43% distributed in the near-infrared spectrum (from 720 to 2500 nm). Since higher reflectivity means better thermal insulation of the film in 400–2500 nm region, the first principle to choose reflective fillers is that the material should show high reflectivity in visible and near-infrared spectrum. Researches show that these fillers can improve the thermal insulation performance of the film obviously compared with the traditional thermal insulation materials. Heat Proofing in Pakistan

Usually, the visible color of the film is decided by the visible color of the fillers, and the fillers show particular color due to its selective reflection and absorption of visible spectrum. For example, white means the filler almost completely reflects all visible spectrum from 400 to 720 nm, whereas black means the filler absorbs almost all visible spectrum and red means the filler can primarily reflect spectrum from 650 to 700 nm, while absorb other spectrums in visible region. Based on these, white is the best color for infrared reflective fillers, for white fillers can reflect away almost all the spectrum in visible bands. For example, the TSR of titanium white is higher than 75%. But on the opposite, black fillers are barely selected for thermal insulation, because it can absorb almost all solar energy in visible spectrum, such as the TSR of carbon black is as low as 3–5%, which means it can absorb 95–97% of the solar energy. How different colors affect the indoor temperature of building has been studied not only theoretically but also experimentally test in different conditions verified that the white fillers show better thermal insulation than fillers with other colors, especially black. Just after hours of solar radiation, the room temperature is 7°C higher when the surface of building is covered with black than white. Taking decorative into account, pigments show particular colors are usually added to coatings; so eventually, the reflection and absorption properties of film in the visible spectrum are affected by both fillers and pigments. Rockline Chemical provides extremely affective solution for roof heat proofing in Pakistan, Heat Proofing in Pakistan

As discussed above, adding reflective fillers into coatings is an effective way to improve thermal insulation performance of the film. In this situation, fillers with high reflectivity at both visible spectrum and near-infrared spectrum bands are good choice. Under this premise, metal, metal oxide, hollow glass beads, fly ash beads and ceramic beads, and other materials with higher reflectivity are mainly selected as functional fillers when reflective thermal insulation coatings are prepared. But it is worth noting that, not only the color but also the structure of fillers affects the thermal insulation performance of the film; for example, metal oxide fillers with nanocrystal structure have better near-infrared reflectivity, which means better thermal insulation performance than with ordinary structure of metal oxide fillers. Heat Proofing in Pakistan

Sometimes, two or more kinds of reflective thermal insulation functional fillers are mixed in order to get better thermal insulation performance of the film. But the truth is that the reflectivity of the mixed fillers is not simply a sum of the reflectivity of each filler. For example, the TSR of CoAl blue and MnSbTi brown is 35.7 and 32.6%, respectively, but if these two fillers were mixed according to a mass ratio 1:1, test results show that the TSR value of the mixture is only 26.9%, which is not only lower than the intermediate value 34.15% but also lower than the minimum TSR value of MnSbTi brown (32.6%). Heat Proofing in Pakistan

To reflective thermal insulation coating systems, as the reflection occurs mainly on the surface of the film, thicker films do not always mean better thermal insulation performance. This is quite different to obstructive thermal insulation coatings. Generally speaking, there is an optimal value thickness of the reflective thermal insulation film; if the thickness of the film is lower than the optimal value, the thermal insulation performance is better when the film is thicker, but if the thickness of the film exceeds the optimal value, increasing the thickness of the film shows little effect on improving the thermal reflection efficiency of the film. This is because when the film is thinner, part of the solar can penetrate the film and be absorbed by the substrate under the film, but when the thickness reaches to a certain value, the substrate is completely covered by the film and the reflectivity is stable at same time; as a result, the thermal insulation effect become steady. Heat Proofing in Pakistan

With reflective thermal insulation functional fillers, films can reflect solar directly back to atmosphere, rather than first absorb and the emission as the thermal conductive coating; so theoretically, the thermal insulation performance of reflective thermal insulation coatings is better than obstructive thermal insulation coatings It is noteworthy that reducing the roughness of the film surface is conducive to improving the thermal reflectivity of the film. Hollow glass microspheres covered with nickel were used as fillers [29]; the results showed that the thermal insulation performance of the film is excellent. ZrO2 ceramic balls coated with potassium silicate have higher light scattering, reflectance, about 10–20 times that of common ZrO2 ceramic balls. Compared with the same size of rutile TiO2 fillers, the effect of modified ZrO2 ceramic ball is improved by 1/3 . Heat Proofing in Pakistan

Fillers with high reflectivity and high emissivity were applied to improve the reflectivity of the films in the near-infrared region (720–2500 nm) and visible region (400–720 nm). Researchers have done much and made big improvements in this area up to now; as a result, reflective thermal insulation coatings have already been studied and used widely. For example, covered with heat-reflective insulation film on exterior walls of building in Hangzhou, China, a typical hot summer and cold winter zone, the surface temperature of the wall can be reduced up to 10°C. By calculating, it was found that the annual air-conditioning electricity saving with heat reflective insulation coating on exterior walls is about 5.8 kWh/(m2 month), which indicated that the energy saving effect with the heat insulation coating is obvious Heat Proofing in Pakistan

With good thermal insulation performance, various reflective thermal insulation coating products can be selected in coating markets, which is now the main product in thermal insulation coating market .Rockline Chemical provides extreamly affective solution for roof heat proofing in pakistan,

2.3. Radiative thermal insulation coatings

Any object exposed to the sunlight can absorb while radiate solar energy at the same time. If the object absorbs more energy from solar than it radiates to the external space, the temperature of the object increases. On the other hand, if the object radiates more energy than it absorbs, the temperature of the object decreases. During this progress, the radiated energy is emitted in the form of invisible infrared light and longer wavelength electromagnetic waves. This radiation caused by molecular, atomic thermal motion is called thermal radiation.

Theoretically, thermal radiation exists between any practicality object. That means when any object radiates the energy of itself into external space, the external space radiates energy back to the object at the same time. Although the two processes always exist at the same time, but as we all know, when the temperature of the object is higher than the external space, the results of thermal radiation are that the object transmits more energy to external space and vice versa. If the temperature between object to external space is the same, there is no temperature change for the object after thermal radiation, for the amount of energy transmit, and accept by object is equal during the whole process. The temperature in outer space is close to absolute 0 K, so it seems that outer space is an ideal energy receptor, which means that any object can radiate the energy of itself into outer space with thermal radiation. But unfortunately, the energy radiation from objects on the ground to outer space is always been impeded by the outer surface atmosphere of the earth. As the atmosphere worked as a barrier between the object and the outer space, so in order to get an ideal thermal radiation, first of all, we make sure the radiation can be successfully transmitted through the atmosphere into outer space. Atmosphere is mainly composed of water vapor and carbon dioxide, and these two substances show a weak absorbance during 8–13 μm spectrum. That is to say, the atmosphere has a high transmission during 8–13 μm radiation, or in other words, when the thermal radiation between object and outer space occurs during 8–13 μm spectrum, the outer surface atmosphere of the earth is no longer a barrier but a “window”; through this “window,” the radiator on the ground can radiate directly into outer space. Usually, it is called “infrared window” in infrared technology.

The radiative thermal insulation coatings are a system with special fillers, which can convert the absorbed energy into molecular vibration and rotational energy; so the absorbed energy can be eventually transmitted to external space in the form of thermal radiation. Based on these, object covered with thermal radiation film can radiate more energy to external space than it absorbs from solar at the certain wavelength; as a result, the radiative thermal insulation film can cool the covered object actively. This thermal insulation mechanism in radiative coatings is quite different from the obstructive and reflective coatings mentioned above. As with either obstructive or reflective fillers, the film can only block extra solar energy passively, but with radiative fillers, the film can radiate the extra solar energy to external space actively.

As discussed above, radiative fillers showed excellent thermal radiation ability when the outer surface atmosphere of the earth is worked as a “window.” So, in order to meet higher emissivity of film, fillers with strong absorption in the band from 8 to 13 μm are the key to coatings. Studies have shown that adding a certain amount of far-infrared fillers into coating system can greatly enhance the infrared radiation ability of the film. Usually, Fe2O3, MnO2, Cr2O3, TiO2, SiO2, Al2O3, La2O3, and CeO with high emissivity are usually used as thermal radiation functional fillers. Meanwhile, materials with antispinel structure doping from a variety of metal oxide doping can be used as thermal radiation functional fillers due to its higher energy emissivity, like ATO, ITO, etc.

One word in all, radiative fillers are the key factor to achieve excellent thermal radiation in coatings; so the development on new radiative fillers in recent years promoted thermal insulation performance of coatings, but the thermal radiation ability of fillers is affected by many factors like the concentration, diameter size, surface properties (roughness/periodicity) of fillers, doping or not, and so on; so the main problem in radiative commercial coatings is that fillers with steady and excellent thermal insulation performance are expensive.

2.4. Composite thermal insulation coatings

As the heat transfer of object is a combination of heat conduction, convection, and radiation, the ideal thermal insulation coating can resist heat transfer, reflect, and radiate the solar energy actively. Although obstructive, reflective, or radiative thermal insulation coatings mentioned above have its own advantage in thermal insulation, the thermal insulation performance with just single mechanism cannot meet the desire for comprehensive thermal insulation; so under this background, composite thermal insulation coatings are designed to achieve a synergistic thermal insulation with obstructive, reflective, and radiative , For example, nanotitanium-oxide-modified hollow beads are used as functional filler; the film shows excellent thermal insulation performance due to the high reflectivity of the titanium oxide and low thermal conductivity of hollow beads at the same time . A composite thermal insulation coating was prepared with obstructive, reflective, and radiative fillers together in Ref. [46]; testing results showed that the thermal insulation grade of the film is R-21.1, the TSR value of the film goes to 0.79, and the energy emissivity value is as high as 0.83. Data show that the film can resist heat transfer effectively, reflect most of the solar energy, and can cool the substrate actively by radiating energy absorbed. Multithermal insulation system with obstructive, reflective, and radiative fillers compatible with either acrylic or fluorocarbon substrate shows better thermal insulation performance than that with just single thermal insulation mechanism filler . So composite thermal insulation coatings now became the main direction of thermal insulation coating research.

3. Application and development of thermal insulation coatings

Covering with thermal insulation coating has been one of the most effective techniques for energy saving. As discussed above, the thermal insulation performance of coatings is mainly affected by functional fillers, but the applicability of coatings is mainly affected by substrate. So when the coating is designed for a particular application, both thermal insulation performance and comprehensive performance like protective, decorative, and other special needs (anticorrosive, waterproof, fireproof, antifouling, conductive, sterilization, and so on) should be considered at the same time. In this situation, the multifunctional coatings with thermal insulation and other special functions can satisfy more to the requirements of market. Just take building energy saving for example, in order to achieve the overall thermal insulation effects, not only varies of thermal insulation coatings for the outside and inside walls of building have been produced. Meanwhile, considering the urgent thermal insulation needs on color steel plate, aluminum profiles, glass doors, and windows in modern building, researchers have been committed to the development of multifunctional coatings that can meet both the thermal insulation and other specific functional requirements of these structural components. To be specified, transparent thermal insulation coatings can be used for windows, thermal insulation, and anticorrosion coating coatings for aluminum profiles, and etc. Therefore, based on the practical application, the multifunctional coatings with thermal insulation and other special functions are the development trend for thermal insulation coatings.

3.1. Transparent thermal insulation coatings

Transparent thermal insulation coating is transparent in the visible light area with semiconductor powder as fillers. Materials with good transmittance on the visible spectrum and high infrared light transmittance can be used as functional fillers, including nanotin oxide antimony (ATO), nanoindium-tin oxide (ITO), etc., so the film with these fillers can show an excellent thermal insulation performance while being transparent .

Due to the unique size effect, localized field effect, quantum effect, and other unique properties, the nanoparticles can obviously improve both the thermal insulation and antiaging properties of the film. The transparent thermal insulation coatings can widely be used in glass doors and windows in modern buildings, automotive glass, and so on. In fact, transparent thermal insulation coatings can almost be used at any substrate with a particular need for both transmittance and thermal insulation needs.

A transparent thermal insulation coating with nano-ATO as filler was prepared and tested; results showed that the coatings show both good transparency and thermal insulation performance due to the use of nano-ATO. Moreover, the thermal insulation effect of the film increases with increasing weight content of ATO Test results also indicated that the transparent thermal insulation coatings with ATO possess good artificial accelerated weathering resistance.

3.2. Vacuum thermal insulation coatings

As thermal conduction caused by the molecular vibration and convection will completely disappear in vacuum, the thermal insulation performance of the film will be outstanding if the film can form a vacuum or near vacuum structure. In 1970s, experts in the United States obtained a high-quality thermal insulation coating, with aerogel as filler; the aerogel was prepared by filling spherical hollow ceramic microbubbles into an inert latex binder (aqueous) through NASA spacecraft insulation material technology. The aerogel then forms a vacuum cavity layer in the film, which can not only obstruct but also reflect solar energy effectively. Tests showed that just brushing a thin layer of the film on the surface of buildings, the room temperature increased in winter but decreased in summer. That means the coating showed an effective thermal insulation effect. Moreover, data show that the film can reach a thermal insulation up to 95%, and as a result, reduced up to 30–60% energy consumption when used on buildings. That means the vacuum thermal insulation coatings are excellent in both thermal insulation and comprehensive performance due to its special structure . And it is considered to be one of the most efficient energy-saving materials with a promising future.

3.3. Nanoporous thermal insulation coatings

As mentioned above, aerogel with vacuum shows an ideal thermal insulation performance when used as fillers. But it is not easy to get a complete vacuum condition in many situations. Under this situation, researchers tried to use aerogel alone as filler. Aerogel basically consists of ultrafine particles and gaseous dispersion medium. Usually, the particles are filled in the pores of the medium’s network structure. It is found that when the pores in network are less than 50 nm, the aerogel can show a very good thermal insulation effect. Actually, the fillers’ ideal thermal conductivity value can even approach zero. So, it is entirely possible to obtain a coating with smaller thermal conductivity value than that of static air (0.023 W•m−1•K−1) with fillers with nanoporous structure , which means a lot to thermal insulation performance of the film. So, fillers with nanoporous structure provided unprecedented opportunities and possibilities for the development of thermal insulation coatings.

Aerogels are low-density solid materials with nanoporous network structures. The aperture of SiO2 aerogel is about 2–50 nm, and the hole rate is high up to 99.8%, and the thermal conductivity value of SiO2 aerogel is 0.008–0.018 W•m−1•K−1 at room temperature, which is much lower than 0.023 W•m−1•K−1. So, SiO2 aerogel is considered to be one of the lowest thermal conductivity materials in the field of thermal insulation. The thermal insulation performance of SiO2 aerogel composites were also prepared and studied. For example, SiO2 aerogel composed with ceramic fibers was studied. As discussed, silica aerogel itself has very low thermal conductivity value on both gas and solid due to its special structure; meanwhile, ceramic fibers can greatly decrease the value of radioactive thermal conductivity of the composite. So as a result, silica aerogel composites show excellent thermal insulation properties. Test showed that the thermal conductivity value of the composite is only 0.017 and 0.042 W•m−1•K−1 accordingly when test at 200 and 800°C [59]. A trimethylchlorosilane-modified SiO2 aerogel was prepared and tested, results indicated that the thermal conductivity of composite is 0.0136 and 0.0284 W•m−1•K−1 at room temperature and 400°C, respectively

With SiO2 aerogel and polyvinylidene fluoride as substrate, a thermal insulation film was prepared and tested. Results indicated that the thermal conductivity of the film is as low as 0.028 W•m−1•K−1 [61]. Meanwhile, the performance of thermal insulation enhanced with the increasing content of SiO2 aerogel.

3.4. Smart thermal insulation coatings

Smart thermal insulation coating, which can insulate heat when the outer temperature is too high and release heat when the outer temperature is too high, has drawn attention in recent years, as this kind of coating has both energy storage and thermal insulation functions. Thermochromic, photochromic, electrochromic, and gasochromic films are demonstrated for energy saving as different kinds of thermal insulation coatings . By just taking thermo-chromic films for example, thermo-chromic materials are capable of changing their optical properties when exposed to heat. The transmittance and reflectance can be significantly altered due to phase transition. Metal oxides such as lower oxides of vanadium, titanium, iron, and niobium can be used as fillers, which means, with these fillers in coating system, the color of the film can change when the temperature changes. With lower transition temperature and sharp transition features, vanadium dioxide (VO2)-based smart coatings have gained much attention in recent years. When the temperature is lower than 68°C (Tc), the structure of VO2 is semiconducting (insulating) monoclinic phase; when the temperature exceeds Tc, the structure turns to metallic tetragonal rutile . The switch between the different structures means different light selectivity, which means, at temperature under Tc, film with VO2 allows transmission of the visible and infrared light, and when the temperature is higher than Tc, the VO2 film allows visible light but blocks IR. As a result, film with VO2 shows variation color when the temperature changes. Researchers have already done much to improve the luminescence transmittance and modulation capability of solar energy .

Based on the adjustability of the coating system, the study on smart thermal insulation coating causes more and more attention from the researchers; so it is worth looking forward to the widespread application of the smart thermal insulation coatings sometime in the future.Rockline Chemical provides extreamly affective solution for roof heat proofing in pakistan,